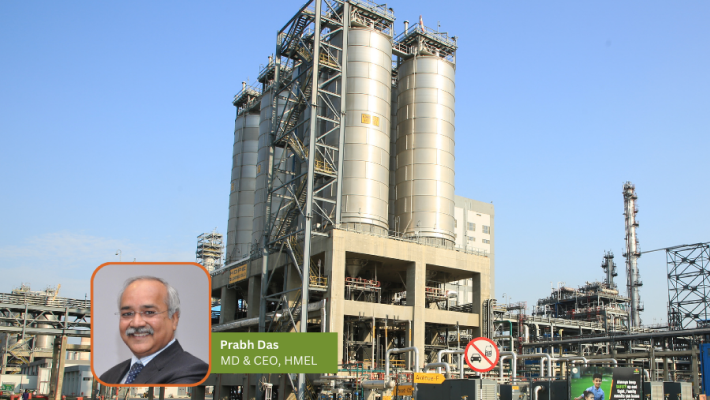

Excerpts from Interview of Mr. Prabh Das, MD&CEO, HPCL-Mittal Energy Limited (HMEL), with Chemical Engineering World (CEW) – August 2023.

What are your thoughts on the recent volatility in the oil market?

Answer:

The oil and gas industry isn’t new to supply disruptions and price volatility. A confluence of economic, geopolitical, trade, policy, and financial factors have exacerbated the issue of underinvestment and triggered a readjustment in the broader energy market. The situation highlights the need for both short-term adaptability and long-term resilience in the global energy landscape. This volatility also accentuates the significance of diversifying geographies, investing in intelligent tools, and fostering collaborations to ensure stability and sustainable growth in an ever-changing market environment.

Insights into the petrochemical complex in Guru Gobind Singh Refinery, how will this investment position HMEL in Indian and global markets?

Answer:

HMEL is responding to reduce the country’s dependence on imports and meet the ever-growing domestic demand for Polypropylene (PP) and Polyethylene (PE) and has undertaken a massive over US$ 3 Billion expansion in the field of petrochemicals at Bathinda. Our world-class integrated complex now has 2.2 Million MT Petrochemical capacity with a Dual Feed Cracker Unit of 1.2 Million MT/annum of Polyethylene (PE) and 1 Million MT/annum of Polypropylene (PP) capacity to cater to all major application segments. With this investment, we aim to diversify the business by reducing our dependence on fuel-intensive products and establishing HMEL as one of the largest PP/PE producers in the Indian petrochemical market.

Tell us about the procurement budget & strategy and how have you balanced risk management, supply chain optimization and green purchasing?

Answer:

HMEL has Enterprise Risk Management Policy to manage the risk associated with commodity price and protect the margins from the price variations due to market volatility. We have in place enterprise risk register that helps in identifying, scaling, and controlling the organization risk in the changing environment. Concurrently, HMEL uses technology, including integrated LP model for feedstock procurement planning and optimizing software for scheduling, which enables us to take strategic decisions and optimize supply chain. Additionally, we have taken initiatives to continuously purchase solar/wind energy in some of our units. HMEL is working towards linking our facilities to renewable and circular feedstock contributing to the carbon neutrality vision of India.

What is the product mix and targeted markets for supplying these petrochemical products?

Answer:

HMEL’s Guru Gobind Singh Polymer Addition Project consists of downstream polymer units to produce LLDPE (Low Linear Density Polyethylene), HDPE (High Density Polyethylene) and Polypropylene. Products from these plants are the building blocks of multiple key industries ranging from packaging material manufacturing to the healthcare industry for the manufacture of disposable syringes, surgical masks; household furniture; consumer durables, textiles, pipe manufacturing; automobile dashboard manufacturing industries etc. The key markets for these polymer products would be the Northern and Western zones of the country as well as overseas.

What are the key challenges in the near foreseeable future to be globally competitive and how are you navigating these to drive the growth?

Answer:

The volatility in oil prices is likely to continue due to geopolitical tensions and complex supply chains, which could keep the industry under pressure in the short run. It requires the players to innovate, invest in technology adoption and forge strategic partnerships. We at HMEL are at the forefront to embrace the latest technologies such as Artificial Intelligence, Robotics Process Automation and Advanced Analytics, etc., which will make our operations more efficient, safe and reliable. Following the mantra of Improve, Integrate and Innovate, we have deployed cutting-edge technologies like Real Time Optimizer, Advanced Process Control, Supply Chain Automation, IIoT, Virtual Reality, Advance Analytics and many more steps are planned towards the digital transformation of HMEL.

Talk to us about the plans to get into Green Hydrogen and investment that have been earmarked.

Answer:

HMEL is actively exploring strategic opportunities in Green Hydrogen and Green Ammonia, recognizing its potential and supporting the country’s sustainable development goals. HMEL has recently forged a powerful partnership with NTPC Green Energy Limited (NGEL) to collaborate in the field of renewable energy and also explore opportunities in the area of green hydrogen & its derivatives (Green Ammonia & Green Methanol). Our Bioethanol Project is in the advanced stage of completion and we have commissioned pilot scale Hydrogen Fuel cell for the supply of power required for charging Forklift Batteries. Moreover, we have implemented multiple schemes to significantly reduce our energy consumption.

How is HMEL adapting to the changing energy landscape balancing the energy trifecta of sustainability resilience & affordability for energy security?

Answer:

Balancing the energy trifecta is an ongoing process that requires adaptation to market dynamics, changing technologies and environmental considerations. HMEL’s future strategy is aligned to achieve the optimal balance of energy supply and demand fulfillment encompassing purported investment in renewable energy for a more secure energy mix and fostering sustainability by marking its footprints in the green sector. Secondly, with our diversification into petrochemicals, HMEL is bolstering resilience by mitigating high dependence on fuel products. And lastly, HMEL continues to leverage advanced technologies and innovation which can lead to breakthroughs that enhance the country’s energy efficiency, resilience, and sustainability.

no updates

no updates