“Recycling” the term is becoming popular in this era to maintain environmental consciousness and sustainability. Recycled plastics have been available over time, and regardless of the steady growth, the recycling segment has been a niche section in this evolving petrochemical market.

The current global energy transition market motivates companies to innovate the market of sustainable and high-quality petrochemicals. Do you want to know what complexities a business needs to overcome to make recycling more feasible in the upcoming years? If yes, check this blog.

Small and large businesses are getting recognized rapidly because of their initiatives to recycle plastics. Acknowledging the effectiveness of recycling is necessary, which relies on the collaboration of multiple stakeholders ranging from end-users to product designers.

Here in the below section, we have mentioned why recycling plastics is tough in this era:

It is tough to differentiate plastics

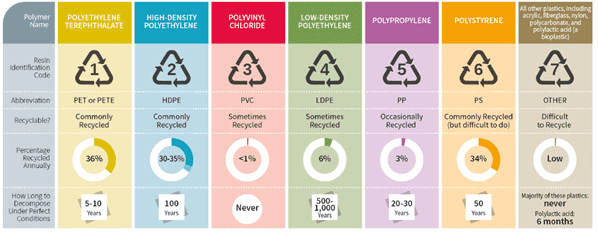

Figure 1: Resin Identification Codes (RIC)

The plastic materials are mostly made with composite materials, which means these materials contain multiple raw materials that make the differentiation more challenging. There are 7 plastic classifications, as mentioned in the picture (Based on the Society of Plastic Industry- 1988 SPI), but there may be thousands of plastic combinations in the end product.

Each plastic item contains various polymers derived from different additives and chemical compounds. It contains additives such as fibers, dyes, and other polymers. The following additions are the impurities that lead to multiple melting points, other plastic properties, and similar resin codes. Dividing the type of plastic waste when it arrives at the sorting plant is a complex task. The sorting method contains density tests and infrared technology; however, these are not entirely precise. Plastics that have a purity level of 96% qualify for the recycling process.

For example, take paper cups since they have polypropylene lining for insulation. These multi-layered complex compositions of the paper cup require significant resources along with the time for recycling. The recycling companies are dedicated to processing such intricate products.

For complete segregation, businesses must opt for advanced sorting ways. In most communities like Minnesota, Saint Paul collects only “necks” bottles marked with 1 or 2 resin codes for recycling projects. The containers that don’t have necks, like trays and tubs, aren’t recyclable even if they are marked with one and two. The plastic bottles are blow-molded, whereas the plastic tubs are injection-molded. During the process of recycling, different additives are used.

Would you invest more in second-hand products? The businesses wouldn’t

Purchasing the products that are recycled means paying a value more than the retail cost for the 2nd hand products. Recently, PCR material has been facing a weak market demand because the virgin counterpart is in the market at a much cheaper cost with better properties. No matter what, the demand for recycled plastic is increasing rapidly.

The consumer goods business is committed to incorporating PCR materials in their consecutive products. Multiple PCR businesses, mainly in China, keep the contracts intricate, including cheaper virgin materials in recycled materials and selling them by claiming them as 100% PCR material.

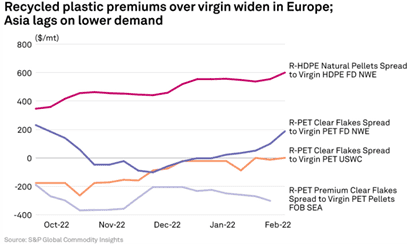

The above picture is from S&P Global, which signifies the major deltas between virgin and recycled materials. Consumer goods companies meet with various complexities like sustainability aims within the decided period. They have more responsibilities than the packaging suppliers to fulfill their commitments.

The suppliers find themselves responsible for incorporating the recycled content even when facing struggles to eliminate potential losses from the contracts. The advanced technologies are in high demand in the industry, which can differentiate and deliver top-notch recycled plastics at the equivalent and low cost compared to virgin material.

The plastics are repurposed and not recycled.

Greenpeace found that no plastics, including items such as soda bottles placed in recycling bins, meet the criteria that need to be labeled “Recyclable,” depending on the standards set by the Ellen MacArthur Foundation New Plastic Economy initiatives. The Plastics should have a 30% recycling rate to meet all these regulations. This rate defines the threshold that plastic can’t come closer to achieving recycling.

Unlike metals and ceramics, plastics also do not “close the loop” because most post-consumer plastics can’t be used for the same application. Single plastic items can go through the recycling process up to 3 times before they reach the state where they can be usable. Even if reused for the same purpose, it must be mixed with virgin resin to foster the quality. Recycling plastics extends their life temporarily and postpones their eventual disposal. This is how we can conclude that all types of plastic end up in the incinerator or landfill.

Only a few businesses make strategies for recycling.

As mentioned earlier, plastic materials are composite materials, so they contain different materials that are complex to differentiate during recycling. Based on recent scenarios, unfortunately, commodity products are designed with recycling in mind. When addressing various factors during the design and manufacturing stage, the products disassemble into the waste fractions, making them different from other materials. To understand this, a specialized professional or a skilled expert is required.

Not every type of recycled plastic has a similar demand in the market

According to Polaris reports, the global recycled plastic market was valued at USD 46 752.4 million in 2021. However, the market is expected to grow with a CAGR value of 7.4% during the forecast. However, the demand is not constant for every type of plastic. The global market mainly demands recycled plastics made of rPET and rHDPE.

Here, rPET is evolving as the fastest-growing recycled plastic-type because of easy sorting and improved collection quantity from the used plastics. In the U.S., 0% of rPET in recycling bins are recycled successfully. The popularity of rPET plastic is rapidly growing, thanks to the textile industry. They play a strong role by utilizing these plastics in producing synthetic fabrics such as polyester.

Consumer goods organizations like P&G and Unilever consider the improved consumer preference for eco-friendly products, and that’s why they contribute to HDPE. Organizations like Unilever collaborate to ensure all plastic packaging is recyclable, compostable, and reusable. It aims to utilize 25% recycled plastic for packaging by 2025. P&G has also aimed to minimize virgin plastic use by 50%.

Well, the above-discussed content emphasizes only the two types of plastics, but five more remain. This is why businesses mostly show their interest in investing in 2 plastic types, rPET and rHDPE.

Final thoughts

Following the above-discussed guide, the plastic recycling process may seem daunting, but it can be easy when you follow the required process. The most common challenges businesses face are market demand disparities, complex distinctions, limitations in the recyclability of certain plastics, technology differences, and the rising demand for significant plastics in the market.

To deal with these complex strategies, the business should adopt smart technology advancements and improve awareness in terms of environmental issues. By beating all these hurdles, we can design a better sustainable future where recycling can become more efficient and appear promising.